Transformers, inductors, motors, and sensors need coil winding. To produce inductance, a copper or aluminum wire is wound around a core in this complicated process. The accuracy and method used in coil winding affect product performance, efficiency, and dependability. This page examines coil winding kinds, processes, materials, equipment, and applications.

Types of Coil Winding

Coil winding methods depend on the coil’s use and desired properties. The main kinds are:

1. Layer Winding

Layer winding requires stacking wire layers properly. This approach is employed in situations needing exact inductance and minimal EMI due to its homogeneity.

2. Winding randomly

Random winding creates a looser coil by wrapping the wire without a pattern. EMI and inductance may increase with this quicker, cheaper technique. Usually utilized in less sensitive applications.

3. Winding Progressively

Progressive winding increases wire pitch as it is coiled. This approach reduces hotspots and improves heat management by equally distributing winding density.

4. Toroidal Winding

Transformers and inductors employ toroidal winding. The wire is twisted through a doughnut-shaped core to create a small, efficient coil with low leakage inductance and EMI.

Steps in coil winding

The coil winding process has numerous crucial phases to assure product quality and performance.

1. Plan and design

Designing the coil entails choosing the turns, wire gauge, and core material. This step demands a solid grasp of electromagnetic principles and application requirements.

2. Materials Preparation

A final design is followed by material preparation. Cut the wire to the right length, prepare the core, and make sure all materials satisfy quality requirements.

3. Set up

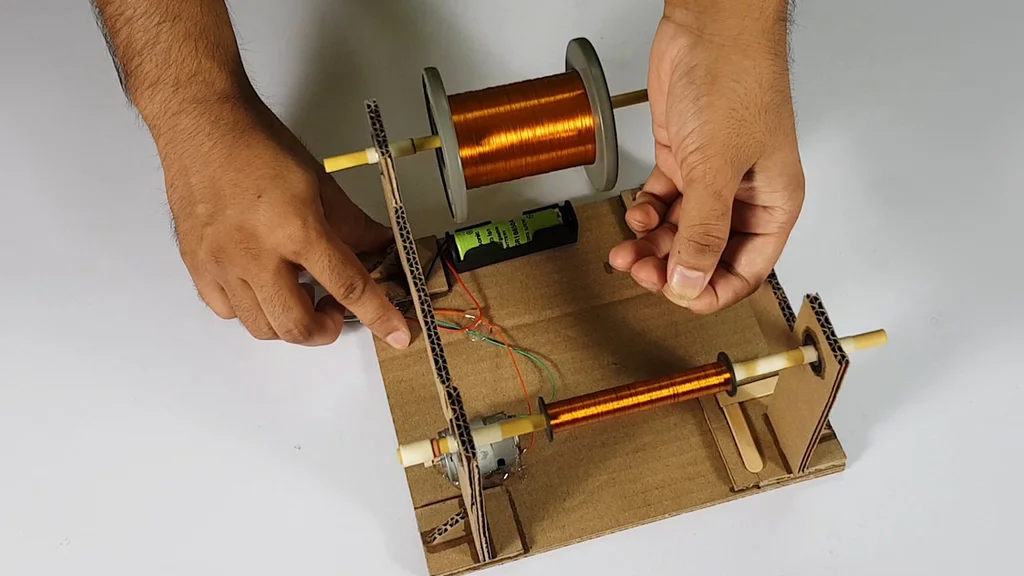

The winding machine is set up as designed. Configure machine settings including winding speed, tension, and pattern.

4. Winding

The wire is carefully twisted around the core in the appropriate pattern. Precision is needed to eliminate overlaps and gaps in this stage.

5. Insulation, Layering

To avoid short circuits and increase longevity, multilayer coils include insulation between layers. This stage may need extra insulation or coatings.

6. Ending

After winding, the coil ends and terminates. Wire ends are connected to terminals or leads to connect the coil to the circuit.

7. Testing/QC

The final coil is rigorously tested to fulfill design and quality criteria. Electrical, mechanical, and environmental stress tests are possible.

8. Final Assembly

Many coiled coils are integrated into bigger components or systems. This stage may include installing the coil, attaching housings, and integrating it.

Advanced Coil Winding Technology

Technological advances in coil winding have improved accuracy, efficiency, and adaptability.

1. High-Tech Materials

New materials including high-temperature superconductors and better insulation have improved coil performance and durability.

2. Improved Automation

CNC and robots improve accuracy and uniformity in modern coil winding devices.

3. Digital Controls

Digital control systems monitor and alter winding parameters in real time, optimizing performance and decreasing waste.

4. Simulating/Modeling

Advanced simulation and modeling technologies let engineers design and tune coils before production, saving money on prototype and testing.

5. IoT integration

The Internet of Things (IoT) improves data collecting and analysis for coil winding machines, improving process management and predictive maintenance.

Conclusion

Electromagnetic component performance, efficiency, and reliability depend on coil winding. Advances in materials, automation, and digital technologies improve coil winding accuracy and adaptability, allowing the manufacturing of more complex devices. Innovative and efficient coil winding processes will become more important as high-performance electronic components become more popular.